What is a Grinding Wheel, and How is it Labeled?

We’ll dive into the grinding wheels, which are essential components for precision grinding work that make all the difference in quality. Understanding how to read the labeling on grinding wheels can greatly enhance the precision and effectiveness of your grinding work.

In this post, we’ll review the main components and labeling of grinding wheels to help you choose the best wheel for your needs. Let's get started on this essential guide to grinding wheel labeling and composition!

연삭 지석은 다양한 재료와 다양한 규격이 결합된 고도의 기술이 담긴 제품입니다. 연삭 가공의 핵심 부품이자, 그 품질을 좌우하는 연삭 지석(숫돌 바퀴)에 대해 알아보려 합니다. 연삭 지석의 표기 방식에 대해 자세히 이해하고 나면, 연삭 가공의 효율성과 정확성을 한 층 더 높일 수 있는데요.

오늘 포스팅에서는 연삭 지석의 구성 요소와 표기 방법에 대해 알아보면서, 연삭 작업의 품질을 높이는 첫걸음으로 함께 시작해볼까요?

What is a Grinding Wheel?

연삭 지석이란 무엇일까요? 🤔

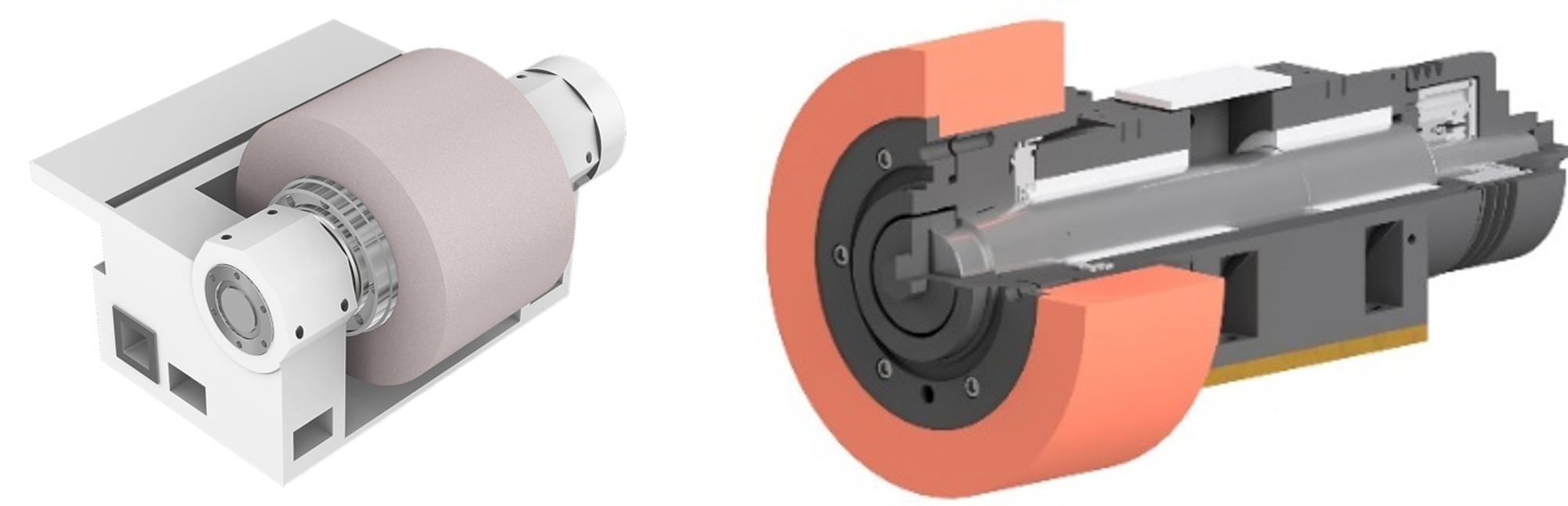

Grinding wheel is indispensable for precisely machining metals, ceramics, and other materials. It’s more than just a stone; it’s a sophisticated assembly of cutting grains bonded together by a matrix, or binder, specifically designed for optimal performance in material removal.

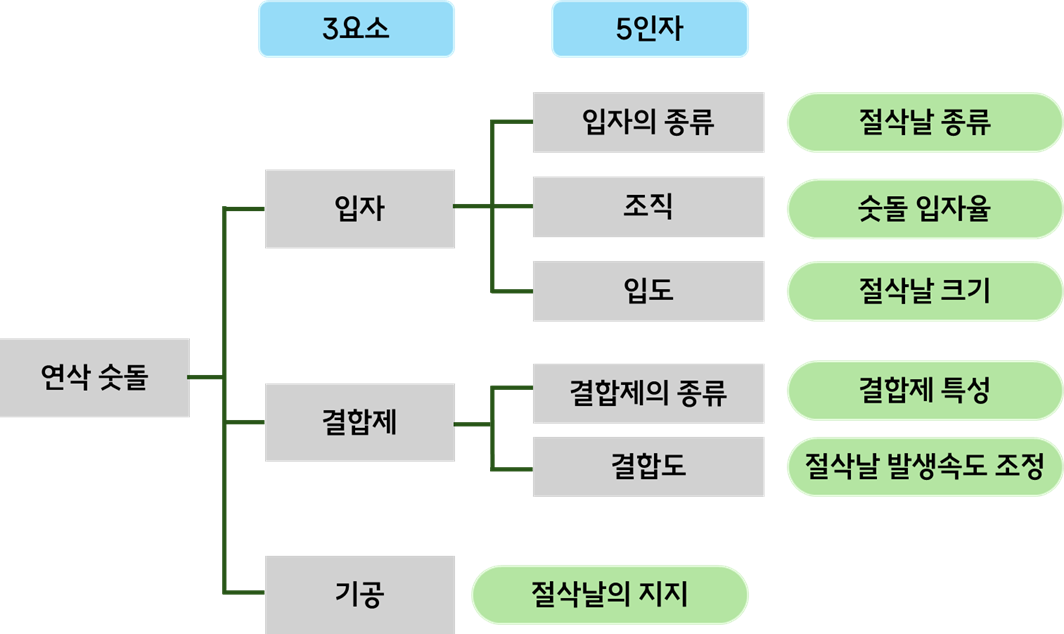

The structure and performance of a grinding wheel depend heavily on its three main elements: Abrasive grains, Bond material, and Pores.

Each of these has a unique role, and they work together to affect the final product's grinding process, efficiency, and quality.

연삭 지석, 흔히 숫돌 바퀴(Grinding Wheel)라고도 불리는 이 도구는 금속, 세라믹 등 다양한 소재를 정밀하게 가공하는데 없어서는 안 될 중요한 도구입니다.

연삭 작업에서 중요한 이 연삭 지석은 단순한 숫돌이 아닌, 절삭 기능을 갖춘 입자와 그 입자들을 결합하는 결합제로 이루어져 있습니다.

특히, 연삭 지석의 구조와 성능은 연삭 입자, 결합제, 그리고 기공이라는 세 가지 요소에 의해 좌우됩니다. 각각의 특성에 따라 연삭 작업의 품질과 효율성을 크게 좌우합니다.

Main Components of Grinding Wheel

연삭 지석의 주요 구성요소

The performance of a grinding wheel is determined by five key factors: abrasive grains, grain size, grade, structure, and bond. Each of these components plays a unique role, and different combinations of these factors alter the wheel's usage and performance.

연삭 지석은 연삭 입자, 입도, 결합도, 조직, 결합제라는 다섯 가지 주요 요소에 따라 그 성능이 결정됩니다. 이 요소들은 각각 다른 역할을 하며, 조합에 따라 연삭 지석의 용도와 성능이 달라집니다.

Let's briefly look at each component :

간단히 구성 요소를 살펴보면 다음과 같습니다 :

Abrasive Grains 연삭 입자

These serve as the cutting edges of the wheel and must be harder than the material being processed.

숫돌의 절삭 날 역할을 하며, 가공할 재료보다 더 단단해야 합니다.

Grain Size 입도

The size of the abrasive particles; lower numbers mean coarser grains, while higher numbers indicate finer grains.

숫돌의 입자 크기를 나타내며, 숫자가 낮을수록 거칠고, 높을수록 고운 입자를 뜻합니다.

Grade 결합도

How strongly the abrasive particles are bonded within the wheel.

입자들이 결합제에 얼마나 강하게 결합되어 있는지를 나타냅니다.

Structure 조직

The size of the pores and the density of the particles in the wheel, categorized into open (coarse) and dense structures.

연삭 지석의 기공 크기 및 입자의 밀도를 의미하며, 거친 조직과 치밀한 조직으로 나뉩니다.

Bond 결합제

The bonding agent that forms the wheel and varies depending on its intended purpose.

연삭 지석을 형성하는 결합 성분으로, 사용 목적에 따라 종류가 다릅니다.

Understanding the definition of a grinding wheel is just the beginning of our journey into the world of precision grinding.

In our next blog post, we’ll dive deeper into grinding wheel label analysis, helping you decode the critical information behind these labels to ensure optimal use and performance. Stay tuned as we continue to explore this fascinating topic in our blog series.

At ORSKOREA, we’re committed to sharing knowledge that empowers professionals in the grinding industry. Don’t forget to subscribe to stay updated on the latest insights and solutions!

연삭 휠의 정의를 이해하는 것은 정밀 연삭 세계로의 여정을 시작하는 첫걸음에 불과합니다. 다음 블로그 포스트에서는 연삭 휠 라벨 분석을 다루며, 라벨에 숨겨진 중요한 정보를 해독하여 최적의 사용 및 성능을 보장하는 방법을 알려드리겠습니다. 이 흥미로운 주제를 심층적으로 다룰 블로그 시리즈를 기대해주세요.

ORSKOREA 블로그에서는 연삭 산업 전문가들에게 도움을 주는 지식을 공유합니다.

공작기계 분야 뿐만 아니라 다양한 산업 분야의 최신 인사이트와 솔루션을 받아보시려면 지금 바로 구독해주세요!

Editted by Yoonseung Han

Project Planning Intern

Written by Benedict (Jungwook) Lee

Production Management Associate

ORSKOREA

ORSKOREA is an ISO9001-certified company, and a leading grinding machines and spindle manufacturer in Korea.

ORSKOREA's product range for grinding machines includes internal, external, centerless, surface horizontal double disc, surface vertical double disc, cylindrical grinding machines and super-finishing machines, turning machines, and special-purpose grinding machines.

For spindles, ORSKOREA manufactures high-frequency spindles, belt-driven spindles, built-in-motor spindles, and hydraulic spindles - all controllable at desired speeds.

For more information, sign up and join ORSKOREA community!