This case involves a Taiyo IGV-4N vertical grinding machine experiencing repeated roundness deviation due to aging.

ORSKOREA implemented a spindle-structure retrofit to improve roundness, as simple maintenance was no longer sufficient.

노후 수직연삭기의 진원도 편차, 근본 해결 방법은?

이번 리트로핏 사례의 대상은 Taiyo IGV-4N 수직연삭기로, 장비 노후화와 함께 가공 공정에서 진원도 편차가 반복적으로 발생하고 있었습니다.

오알에스코리아는 단순 정비로는 한계가 있다고 판단해, 진원도 개선을 목표로 주축 스핀들 구조를 포함한 리트로핏을 진행했습니다.

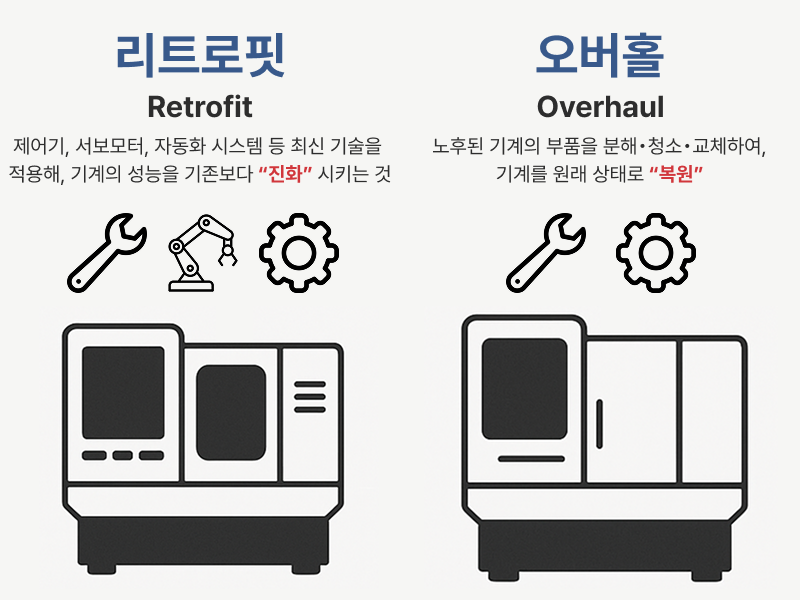

What is retrofit?

리트로핏이란?

Retrofit is a solution that improves machine accuracy, performance, and safety by upgrading key components such as control systems, drive systems, spindles, and safety devices while retaining the original machine structure.

For a detailed explanation of retrofit concepts and real-world applications, see the article below!

리트로핏은 기존 기계 구조를 유지한 상태에서 제어계, 구동계, 스핀들, 안전장치 등 핵심 구성 요소를 최신 기술로 교체하거나 업그레이드해 정밀도와 생산성, 안전성을 향상시키는 기술입니다.

자세한 리트로핏 개념과 적용 사례가 궁금하다면 아래 아티클을 먼저 확인해 보세요!

How Has the Taiyo IGV-4N Changed After ORSKOREA’s Retrofit?

오알에스코리아가 리트로핏한 Taiyo IGV-4N 어떻게 달라졌을까요?

Taiyo Vertical Grinding Machine Retrofit Before (Left), Taiyo Vertical Grinding Machine Retrofit After (Right)Taiyo 수직연삭기 리트로핏 전 (좌) , Taiyo 수직연삭기 리트로핏 후 (우) ⓒ ORSKOREA 오알에스코리아

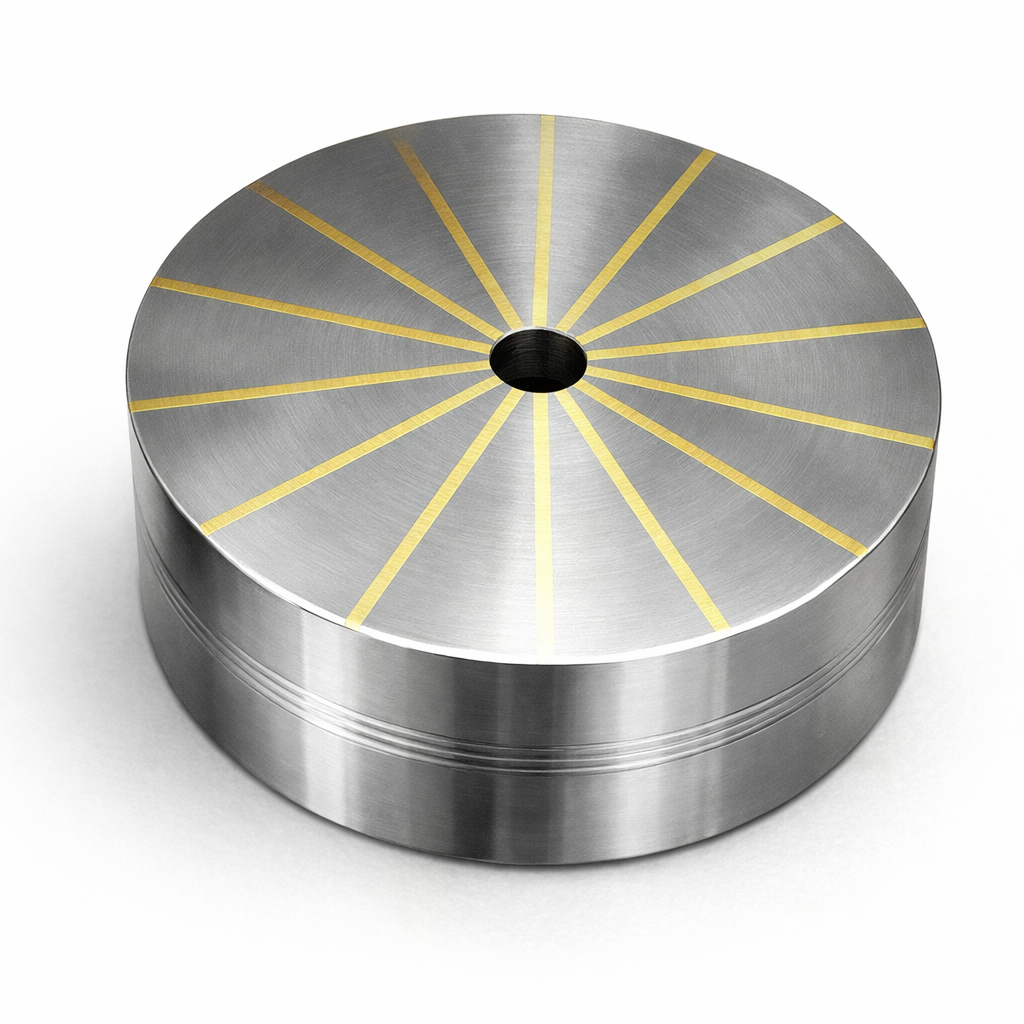

In this Taiyo IGV-4N vertical grinding machine retrofit, the most critical focus was modifying the existing collet-based spindle structure to a magnetic chuck with a shoe support system.

This approach went beyond simple repair, representing a structural retrofit designed to address the root cause of roundness deviation.

이번 Taiyo IGV-4N 수직연삭기 리트로핏에서 가장 중요하게 고려한 부분은기존 콜렛(collet) 방식 주축 구조를 마그넷척 + 슈(Shoe) 지지 방식으로 개조한 점입니다.

이는 단순한 수리 차원의 접근이 아닌, 반복적으로 발생하던 진원도 편차의 원인을 구조적으로 개선하기 위한 변경이었습니다.

Why Did the Collet System Have Its Limitations?

왜 콜렛 방식은 한계가 있었을까?

The existing collet-based system was effective under certain conditions; however, it had the following structural limitations:

- Under high cutting loads or when machining heavy workpieces

→ increased risk of micro-slippage and vibration - Designed primarily for round or simple geometries

→ limited ability to securely support complex-shaped workpieces - Clamping-induced center alignment deviation

→ unfavorable for maintaining consistent roundness

As a result, the recurring roundness deviation was caused not by component wear, but by the workpiece support method itself.

기존 콜렛 방식은 특정 조건에서는 효과적이지만,다음과 같은 구조적 제약을 가지고 있었습니다.

- 절삭 부하가 크거나 공작물이 무거운 경우

→ 미세한 미끄러짐 및 진동 발생 가능 - 원형 또는 단순 형상 위주의 고정 방식

→ 복잡한 형상 공작물의 안정적 지지 어려움 - 클램핑 시 중심 정렬 편차

→ 진원도 유지에 불리

즉, 반복되는 진원도 편차는 부품 노후보다 ‘공작물 지지 방식’에서 비롯된 문제였습니다.

What Changed with the Magnetic Chuck and Shoe Support System?

마그넷척 + 슈 지지 방식으로 무엇이 달라졌나?

The magnetic chuck and shoe support system applied through this retrofit was designed specifically to improve roundness.

- Magnetic chuck

→ uniformly holds the entire workpiece, increasing the effective contact area - Shoe support structure

→ suppresses lateral movement during grinding, improving machining stability - Simplified setup

→ reduces operator-dependent variation and ensures repeatable precision - Improved machining accessibility

→ enables stable processing of workpieces with various shapes

Through these structural changes, workpiece stability during grinding was significantly improved, resulting in a direct reduction in roundness deviation.

리트로핏을 통해 적용한 마그넷척 + 슈 지지 방식은 진원도 개선을 목적으로 설계된 구조입니다.

- 마그넷척

→ 공작물 전체를 균일하게 흡착해 접지면 확대 - 슈(Shoe) 지지 구조

→ 연삭 중 측면 흔들림 억제, 가공 안정성 향상 - 셋업 간소화

→ 작업자 편차 감소, 반복 정밀도 확보 - 가공 접근성 향상

→ 다양한 형상의 공작물 대응 가능

이러한 구조 변경을 통해 연삭 중 공작물의 안정성이 크게 개선되었고, 결과적으로 진원도 편차를 줄이는 데 직접적인 효과를 가져왔습니다.

What is the effect of the retrofit on the vertical grinding machine?

수직연삭기의 리트로핏 효과는?

The Taiyo IGV-4N vertical grinding machine retrofit offers the following practical benefits compared to simple repairs.

이번 Taiyo IGV-4N 수직연삭기 리트로핏은단순한 수리와 비교했을 때, 장비 운영 전반에서 다음과 같은 실질적인 효과를 제공합니다.

1. Equipment Life Extension

1. 장비 수명 연장

Vertical grinding machine repairs typically focus on restoring worn-out components, but this retrofit improved the structure itself, which was the root cause of the roundness issues.

• Retained the existing machine structure

• Redesigned the spindle and workpiece support system

Through these changes, the equipment’s remaining service life was extended, and stable operation was achieved without the need for new equipment.

수직연삭기 수리는 주로 마모 부품을 복구하는 데 초점이 맞춰져 있지만, 이번 리트로핏은 진원도 문제의 원인이 된 구조 자체를 개선하는 방식으로 진행되었습니다.

• 기존 기계 구조를 유지하면서

• 주축 스핀들 및 공작물 지지 방식을 재설계

이를 통해 장비의 잔존 수명을 연장하고, 신규 설비 도입 없이도 안정적인 운용이 가능해졌습니다.

2. Cost Reduction

2. 비용절감

When roundness issues occur in aging vertical grinding machines, equipment replacement is often considered.

However, in cases like this, applying a retrofit results in:

• Significant reduction in initial investment costs compared to new equipment

• Utilization of existing equipment and installation environment

• Reduction in unnecessary parts replacement and recurring repair costs

From a Total Cost of Ownership (TCO) perspective, this makes retrofit a cost-effective choice.

노후 수직연삭기에서 진원도 문제가 발생할 경우, 신규 장비 교체가 검토되는 경우가 많습니다.

그러나 이번 사례처럼 리트로핏을 적용하면:

• 신규 장비 도입 대비 초기 투자 비용 대폭 절감

• 기존 설비·설치 환경 그대로 활용

• 불필요한 부품 교체 및 반복 수리 비용 감소

총 소유 비용(TCO) 관점에서 합리적인 선택이 됩니다.

3. Simplified Maintenance

3. 유지보수 간소화

The previous collet system required frequent adjustments and was susceptible to setup variation, but after applying the magnetic chuck + shoe support system, the following changes occurred:

• Simplified setup structure

• Reduced variation due to operator skill level

• Improved access for inspection, cleaning, and maintenance

As a result, maintenance burden was reduced, and equipment stability was enhanced.

기존 콜렛 방식은 셋업 편차와 반복적인 정밀 조정이 필요했지만, 마그넷척 + 슈 지지 방식 적용 이후에는 다음과 같은 변화가 있었습니다.

• 셋업 구조 단순화

• 작업자 숙련도에 따른 편차 감소

• 점검·청소·관리 접근성 향상

결과적으로, 유지보수 부담이 줄고 장비 운영의 안정성이 높아졌습니다.

4. Stabilized Machining Quality

4. 가공 품질 안정화

The most significant effect of this retrofit was the stabilization of machining quality through the reduction of roundness deviation.

• Improved workpiece support stability

• Suppression of vibration and slippage during grinding

• Ensured quality consistency in repeated machining

This not only improved the quality but also enhanced the reliability of the entire precision machining process.

이번 리트로핏의 가장 큰 효과는 진원도 편차 감소를 통한 가공 품질의 안정화입니다.

• 공작물 지지 안정성 향상

• 연삭 중 진동 및 미끄러짐 억제

• 반복 가공 시 품질 재현성 확보

이는 단순한 품질 개선을 넘어, 고정밀 부품 가공 공정 전반의 신뢰도 향상으로 이어집니다.

Retrofit Feasibility to Consider Before Equipment Replacement

설비 교체 이전에 검토해야 할 리트로핏 가능성

If challenges such as process stability, cycle time improvement, and quality deviation reduction are occurring in aging equipment, it is worth considering retrofit before opting for full equipment replacement.

Especially for companies that have machine tools over 10 years old, or need to simultaneously consider precision, export certification, and smart factory transition, retrofit can be a practical alternative.

ORSKOREA has over 25 years of technical experience in repair, maintenance, and retrofit services for major global grinding machine and spindle brands from Japan, Germany, and Switzerland. Rather than simple maintenance, we focus on making informed, practical decisions based on each machine’s intended application and required machining accuracy to determine the most appropriate approach.

Based on the equipment's condition and current status, we can provide a technical review of retrofit possibilities. We will continue to share various retrofit case studies in the future, so please stay tuned.

노후화된 설비에서 공정 안정성 확보, 사이클 타임 개선, 품질 편차 감소와 같은 과제가 발생하고 있다면, 장비 교체에 앞서 리트로핏이라는 선택지를 먼저 검토해 볼 필요가 있습니다. 특히 10년 이상 사용한 공작기계를 보유하고 있거나, 정밀도·수출 인증·스마트팩토리 전환을 동시에 고려해야 하는 기업이라면 리트로핏은 현실적인 대안이 될 수 있습니다.

오알에스코리아는 일본, 독일, 스위스를 비롯한 주요 글로벌 연삭기·스핀들 브랜드를 대상으로 25년 이상 수리·보수 및 리트로핏을 수행해 온 기술 노하우를 보유하고 있으며, 단순 정비가 아닌 장비의 사용 목적과 가공 정밀도를 기준으로 한 합리적인 판단을 통해 최적의 방향을 제안해 왔습니다.

장비의 사용 조건과 현재 상태를 바탕으로 리트로핏 적용 가능성에 대한 기술적 검토가 가능합니다. 앞으로도 다양한 리트로핏 사례를 지속적으로 공유할 예정이니 관심 있게 지켜봐 주시기 바랍니다.