Showcasing Precision:

Our Grinding Machines and Spindles

at GrindingHub

Around 500 renowned manufacturers from 31 countries showcased numerous innovations across the entire grinding technology process chain at the trade show.

ORSKOREA also participated, exhibiting various products such as grinding machines, bearings, and spindles.

Let's dive into the GrindingHub 2024 exhibition!

국제 연삭기술 박람회인 GrindingHub 2024가 2024년 5월 14일부터 17일까지 슈투트가르트에서 열렸습니다.

31개국에서 온 약 500개의 유명 제조기업에서 무역 박람회에서 연삭 기술 프로세스 체인 전체에 걸쳐 수많은 혁신을 선보였습니다.

이번 행사에는 오알에스코리아도 참가해 연삭 기계, 베어링, 스핀들 등 다양한 제품을 전시했는데요.

그렇다면 GrindingHub는 어떤 전시회일까요?

Overview of GrindingHub

GrindingHub 전시회란?

GrindingHub is the new international trade fair for grinding technology and superfinishing.

The trade fair’s focus is on all aspects of value creation in this technology area. The centre stage is taken by grinding machines, tool grinding machines, and abrasives.

All the relevant software tools, the process periphery, and the measuring and testing equipment needed for QM processes relating to grinding are presented, keeping the entire production environment of grinding technology in view.

It was a meaningful time for leading machine tool companies from various countries to participate in GrindingHub, and for ORSKOREA to exhibit there.

The internationally oriented trade fair starts with a hybrid concept. Accompanying the event and between events, GrindingHub offers digital formats for matchmaking, web seminars, and conferences as well as the communication of current trends and innovations across all channels.

GrindingHub는 연삭 기술 및 슈퍼피니싱 분야의 국제적인 혁신 플랫폼으로, 기술 분야에서 가치를 창출할 수 있는 모든 측면에 주목합니다. 연삭기, 공구 연삭기 및 연마재가 주로 전시됩니다.

연삭과 관련된 QM 프로세스에 필요한 모든 관련 소프트웨어 도구, 프로세스 주변 장치 및 측정 및 테스트 장비가 제시되어 연삭 기술의 전체 생산 환경을 볼 수 있습니다.

전 세계의 유수한 공작 기계 회사가 이 GrindingHub에 참여했고, 오알에스코리아 또한 함께 전시할 수 있어 뜻깊은 시간이었습니다.

국제적으로 지향하는 무역 박람회는 하이브리드 개념으로 시작됩니다. GrindingHub는 이벤트와 함께 그리고 이벤트 사이에 모든 채널에서 최신 트렌드와 혁신을 전달하는 것과 더불어 매치메이킹, 웹 세미나 및 컨퍼런스를 위한 디지털 형식을 제공합니다.

ORSKOREA's Grinding Solutions

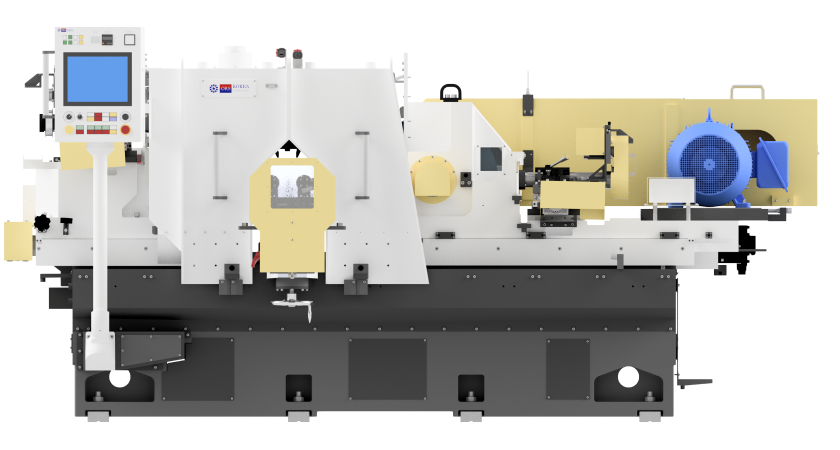

Grinding Machine SGI 150, SGDV 585i, SGC 500

One of ORSKOREA's main products is an ultra-precision grinding machine. Unlike typical machine tools, grinding machines are designed to perform machining with extremely high precision and surface quality, using high-speed rotating grinding wheels to process workpieces within little tolerances.

오알에스코리아의 주요 제품 중 초정밀 연삭 기계가 있습니다. 연삭 기계는 일반적인 공작 기계와 달리 매우 높은 정밀도와 표면 품질이 요구되는 가공을 수행하는 기계로, 고속회전하는 연삭 숫돌(grinding wheel)을 사용해 공작물(workpiece)에 대해 매우 작은 공차 내에서 가공을 수행합니다.

At GrindingHub 2024, grinding machines SGI 150, SGDV 585i, and SGC 500 were showcased.

GrindingHub 2024에는 연삭 기계 중 SGI 150, SGDV 585i, SGC 500을 선보였는데요.

SGI 150

SGI 150 Naming Rule & Models

SGI 150 is an Internal Grinding Machine, with the SGI model name derived from "Smart & Strong Grinding Internal." SGI is the machine used to automatically grind the inner diameter of cylindrical objects made of metal materials. And the number following "SGI" represents the maximum workable outer diameter size (mm). There are more SGI models: 40, 120, 200W, 250, 300.

SGI 150는 내경연삭기 제품으로, SGI 모델명은

Smart & Strong Grinding Internal에서 유래되었습니다.

SGI 뒤에 있는 숫자는 최대 작업가능 외경(mm)를 의미합니다. SGI 제품은 150외에도 40, 120, 200W, 250, 300이 있습니다.

SGI 150 Overview

In the case of the grinding type, the product features NC oscillation or plunge capabilities, allowing for the internal grinding of inner diameters to achieve elaborate shapes and surface quality. And, this technology is typically controlled by Computer Numerical Control (CNC), allowing for precise and automated control of oscillation or plunge movements. Also, the slide transport system can be adapted to various structures according to the product features manufactured by our customers.

연마 방식의 경우, NC 진동 또는 플런지 기능을 특징으로 하여 내경의 정밀한 형상과 표면 품질을 달성할 수 있습니다. 주로 컴퓨터 수치 제어(CNC)에 의해 제어되어 진동이나 플런지 동작을 정밀하게 자동으로 제어할 수 있습니다. 또한 슬라이드 이송 시스템은 고객 원하는 제품 특성에 맞게 다양한 구조로 조절할 수 있습니다.

Key Features of SGI 150

● Optimized Machine Frame 최적화된 기계 프레임

The casting structure of SGI 150 has a sturdy basic design. Also, it minimizes changes in the degree over time by adopting a 3-point support system.

SGI 150의 주조 구조는 견고한 기본 설계를 갖추고 있습니다. 또한, 3점 지지 시스템을 채택하여 시간이 지나면서 발생할 수 있는 변형을 최소화합니다.

● High-Frequency Spindle System 고주파 스핀들 시스템

Exceptional grinding performance for high-speed, high-rigidity applications, guaranteeing ultra-precise finishes

고속 및 고강성 적용을 위한 뛰어난 연삭 성능을 제공하여 초정밀 마감을 보장합니다.

● Automatic Loading 자동 로딩

Equipped with efficient automatic loading, ensuring high customer productivity and minimizing downtime

효율적인 자동 로딩 시스템을 갖추어 고객의 생산성을 높이고 가동 중단 시간을 최소화합니다.

● Dressing 드레싱

Designed to ensure quality stability through complementary programs and support for high-speed dressing with high-frequency spindle type.

보완 프로그램을 통해 품질 안정성을 보장하며, 고주파 스핀들 타입을 지원하여 고속 드레싱이 가능합니다.

SGDV 585i

SGDV 585i Naming Rule & Models

SGDV Series are Vertical Type Double Grinding Machine products, with the SGDV model name derived from "Smart & Strong Grinding Doubledisc Vertical."

The number following "SGDV" represents the outer diameter size of the grinding wheel (mm). ORSKOREA have total 5 SGDV models: 360, 510, 585, 585i, 760.

Vertical Type Double Grinding Machine(수직 양두연삭기) 제품으로, SGDV 모델명은 Smart & Strong Grinding Doubledisc Vertical에서 유래되었습니다.

SGDV 뒤에 있는 숫자는 외경 지석 지름의 길이(mm)를 의미합니다. 오알에스코리아에는 360, 510, 585, 585i, 760 총 5개의 SGDV 모델이 있습니다.

SGDV 585i Overview

SGDV 585i uses two vertical grinding wheels and can grind both sides of the material.

It maximizes productivity by precisely processing multiple products simultaneously.

It is an efficient grinding method that processes can achieve flatness and parallelism, reduce cycle time, and minimize manufacturing costs.

수직 방향으로 2개의 지석(grinding wheel)을 사용하며, 소재의 양면을 동시에 연삭할 수 있습니다. 여러 제품을 동시에 정밀 가공하여 생산성을 극대화할 수 있습니다.

평면도와 평행도를 달성할 수 있는 효율적인 연삭 방법을 사용함으로써 가공시간(cycle time)을 줄이고, 대량생산에 있어 비용을 최소화합니다.

Key Features of SGDV 585i

● High-Rigidity, High-Volume Grinding 높은 강성, 대용량 연삭 가능

Inside the spindle, it consists of cylindrical roller bearings and TAC bearings for ultra-precise and high rigidity, demonstrating the strong grinding power and quality of units

스핀들 내부는 원통형 롤러 베어링과 TAC 베어링으로 구성되어 초정밀 및 고강성을 자랑하며, 뛰어난 연삭력과 유닛 품질을 보여줍니다.

● Clear superiority over general spindles 일반 스핀들 대비 명확한 우위

Since main shaft and flange are manufactured as an integrated forging product, they realize a clear superiority from general spindles under long-term use conditions

주축과 플랜지를 일체형 단조 제품으로 제작하여 장기 사용 조건에서도 일반 스핀들에 비해 명확한 우위를 실현합니다.

● Precision Alignment for Specialized Grinding 전문 연삭을 위한 정밀 정렬

Through-feed method ensures that the workpiece maintains a perfect right angle of the grinding cross-section to grinding reference plane, enabling high-accuracy and consistency in the final product

통과식 방식을 통해 작업물이 연삭 기준면에 대해 완벽한 직각을 유지할 수 있도록 하여, 최종 제품의 고정밀도와 일관성을 보장합니다.

● Reduced Training Time with User-Friendly Interface

사용자 친화적 인터페이스로 교육 시간 단축

Intuitive interface minimizes the need for extensive training, allowing operators even with little experience, can easily get used to.

직관적인 인터페이스로 광범위한 교육이 필요하지 않으며,

경험이 적은 작업자도 쉽게 적응할 수 있습니다.

SGC 500

SGC 500 Naming Rule & Models

SGC series are the Centerless Grinding Machine products, the number following "SGC" indicates the width of the grinding wheel (500 mm). ORSKOREA has 4 SGC Series: 200, 300, 500, 500K.

Centerless grinding machine is designed for shaping and finishing cylindrical workpieces without requiring a center point, fully automated with a CNC system.

SGC 시리즈는 Centerless Grinding Machine (무심연삭기) 제품으로, SGC 뒤에 있는 숫자는 지석(Grinding wheel)의 폭 (500mm)을 의미합니다. 오알에스코리아의 SGC 제품에는 200, 300, 500, 500K 총 4가지가 있습니다.

무심연삭기는 중심점을 필요로 하지 않고 원통형 공작물을 성형하고 마무리하는 연삭기로, CNC 시스템을 통해 완전 자동화된 상태에서 작동합니다.

SGC 500 Overview

ORSKOREA's Centerless Grinding Machine supports two grinding methods—' Through Feed' and 'In-Feed'—boosting the efficiency of external diameter grinding for cylindrical workpieces. This makes it suitable for the precision grinding of various components, including bearings, shafts, compressor sleeves, and common rail pumps.

The machine’s slide transport system, crucial for precision, can be adapted to different structures based on the specific needs of the customers' products, enhancing flexibility and performance.

And 'Traverse Type Point Diamond Dresser' enables more accurate dressing than competing systems, reducing the need for frequent wheel replacements and ensuring consistent precision.

오알에스코리아의 무심연삭기는 ‘스루 피드(Through-Feed)’와 ‘인피드(In-Feed)’라는 두 가지 연삭 방법을 지원하여 원통형 공작물의 외경 연삭 효율을 높입니다. 이를 통해 베어링, 샤프트, 컴프레서 슬리브, 커먼레일 펌프 등 다양한 부품을 정밀하게 연삭할 수 있습니다.

기계의 정밀도에 큰 영향을 미치는 슬라이드 이송 시스템은 고객이 제조하는 제품의 특성에 맞춰 다양한 구조로 조정할 수 있어 유연성과 성능을 향상시킵니다.

그리고 '트래버스 타입 포인트 다이아몬드 드레서(Traverse Type Point Diamond Dresser)'를 사용해 다른 시스템에 비해 더 정확한 드레싱을 가능하게 하며, 휠 교체 빈도를 줄이고 일관된 정밀도를 유지할 수 있습니다.

Key Features of SGC 500

● Continuous Grinding 연속 연삭기

Centerless grinder SGC series can continuously grind cylindrical surfaces using a support plate without supporting the chuck or workpiece center.

센터리스 연삭기 SGC 시리즈는 척이나 작업물의 중심을 지지하지 않고, 지지판을 사용하여 원통형 표면을 연속적으로 연삭할 수 있습니다.

● High rigidity cast iron structure 고강성 주철 구조

High-rigidity casting iron structure provides exceptional vibration damping and thermal stability.

고강성 주철 구조는 뛰어난 진동 흡수 능력과 열 안정성을 제공합니다.

● Reliable Precision in Demanding Conditions

까다로운 조건에서도 신뢰할 수 있는 정밀도

This robust foundation ensures that your grinding process remains precise and accurate, even under demanding conditions.

연삭 기계의 견고한 기반은 까다로운 작업 조건에서도 연삭 공정이 정밀하고 정확하게 유지되도록 보장합니다.

● User-Friendly Interface 사용자 친화적 인터페이스

Intuitive interface minimizes the need for extensive training, allowing operators even those with little experience, can easily get used to.

직관적인 인터페이스로 광범위한 교육이 필요하지 않으며, 경험이 적은 작업자도 쉽게 적응할 수 있습니다.

ORSKOREA's Grinding Solutions

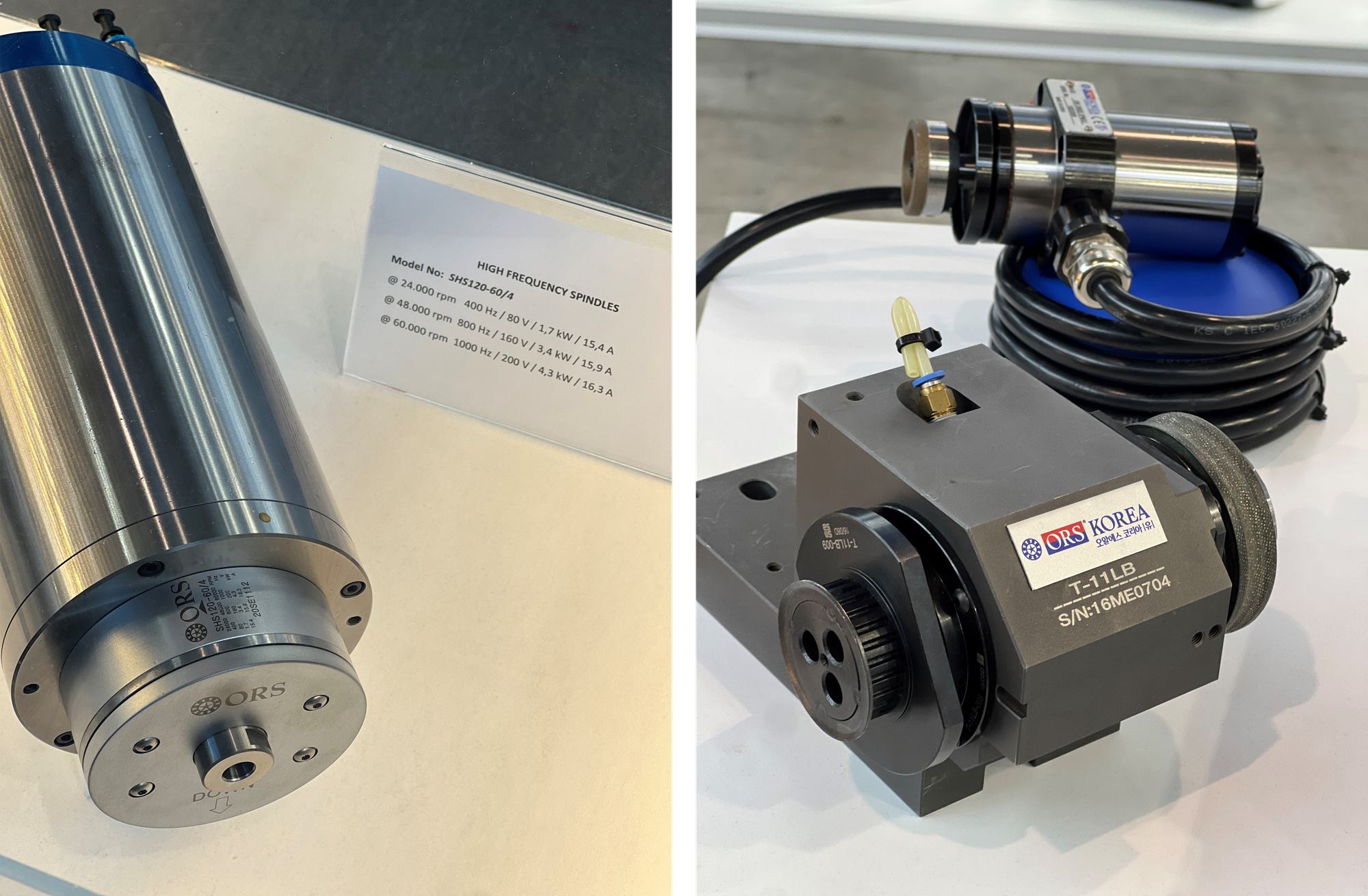

SHS | SHX High Frequency Spindles

High-Frequency spindles, backed by our patented technology have two models:

SHS and SHX.

Our spindles are prepared to grind at high speeds from 15,000 to 120,000 rpm. With multiple tab structures, it can boost high efficiency balancing performance, achieving low noise and vibration and easy housing replacement for smooth installation.

오알에스코리아만의 특허 기술로 뒷받침된 고주파 스핀들은 SHS와 SHX 두 가지 모델로 제공됩니다.

고주파 스핀들은 15,000에서 120,000rpm의 고속 연삭이 가능하도록 설계되었습니다. 다중 탭 구조를 통해 고효율 밸런싱 성능을 발휘하며, 저소음 및 저진동을 실현하고 용이한 하우징 교체로 매끄러운 설치가 가능합니다.

In addition, ORS Bearings also showcased high-precision spindle bearings, various ground parts, etc. at the exhibition. These bearings are used in various industries such as automotive and aerospace components.

Check more information about ORS Bearings through ORS Bearings homepage!!

또한 ORS Bearings에서 고정밀 스핀들 베어링, 다양한 연삭 부품 등도 전시회에 출품했습니다. 이렇게 생산된 베어링은 자동차, 항공부품 등 다양한 분야에 활용됩니다.

ORS Bearings의 베어링에 대한 상세 내용은 ORS Bearings 홈페이지를 통해 확인하실 수 있습니다!!

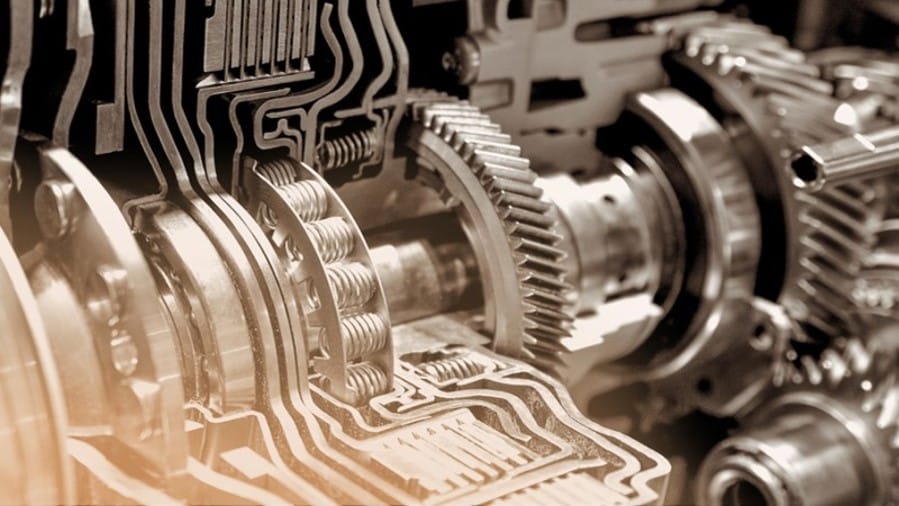

Manufacturing market of Germany and Europe

Germany and Europe's manufacturing market is renowned for producing high-precision automotive and aerospace parts. Automotive components, including engine systems, transmission parts, and modules for hybrid and electric vehicles, are produced using advanced grinding machines. Aerospace parts such as engine rotors, airframes, and landing gears, which demand extreme precision, also rely on grinding technology. Bearings play a crucial role in the production of these components.

독일과 유럽의 제조업 시장은 고정밀 자동차 및 항공 우주 부품 생산으로 잘 알려져 있습니다. 엔진 시스템, 변속기 부품 및 하이브리드 및 전기차 모듈을 포함한 자동차 부품은 첨단 연삭기계를 통해 생산됩니다. 항공기 엔진 로터, 기체 및 랜딩 기어와 같은 항공우주 부품도 높은 정밀도를 요구하며 연삭 기술에 의존합니다. 이러한 부품의 생산에는 베어링이 필수적입니다.

ORSKOREA, a leading manufacturer of grinding machines and spindles, is at the forefront of this industry, offering innovative products that are essential for producing high-quality bearings for the automotive and aerospace sectors, thus supporting the growing demand for precision in these markets.

오알에스코리아는 연삭기계와 스핀들을 제작하는 선도적인 기업으로, 자동차 및 항공우주 분야에 필요한 고품질 베어링을 생산하는 데 필수적인 혁신적 제품을 제공합니다. 이를 통해 독일 및 유럽 시장에서 정밀 부품에 대한 수요 증가에 대응하고 있습니다.

Focus on grinding technology :

Current trends at GrindingHub 2024

GrindingHub 2024의 최신 트렌드 :

연삭기술 중심으로

위 내용은 GrindingHub 2024에서 선보인 일부 솔루션과 기술적으로 주목할 부분입니다.

1️⃣ New grinding machines and grinding concepts

Modular construction kits enable flexible grinding machine designs that enhance cost-effectiveness and reduce delivery times.

새로운 연삭 기계와 연삭 공정을 선보이며 응용분야에 유연하게 적용

모듈식 구성 키트를 통해 다양한 연삭기 설계가 가능해져 비용 효율성을 높이고 납기를 단축합니다.

2️⃣ Simplified process design and planning by New Software Solution

Innovative software like SIGSpro simplifies process design and planning, especially in the implementation of power skiving tools.

새로운 소프트웨어 솔루션으로 프로세스 설계 및 계획 간소화

SIGSpro와 같은 혁신적인 소프트웨어가 공정 설계와 계획을 단순화하며, 특히 파워 스카이빙 도구 구현에 도움이 됩니다.

기어생산을 위한 대체 공정. 다양한 기어를 생산 가능하다는 것이 장점

3️⃣ Efficient process control of grinding machine

Efficient process control requires considering the entire grinding machine along with its peripherals, such as lubricant systems.

효율적인 연삭 기계 공정 제어

효율적인 공정 제어를 위해 연삭기와 윤활 시스템과 같은 주변 장치를 전체적으로 함께 고려해야 합니다.

4️⃣ Additive manufacturing opens new design possibilities for abrasives

Additive manufacturing of abrasives allows new design possibilities in grinding wheels and enhances process productivity and results.

적층 제조 공정을 통해 연마재에 대한 새로운 설계 가능성 열기

연마재의 적층 제조는 구성요소 측면에서 연삭 휠 설계의 설계의 자유도를 높여, 공정 생산성과 가공 결과를 향상시킵니다.

5️⃣ Automation increases productivity

Advanced automation techniques address the shortage of skilled workers while boosting productivity in manufacturing processes. As an example of the methods presented at GrindingHub, there is a method that supplies raw materials in bulk.

자동화 기술을 통해 생산성 향상

첨단 자동화 기술이 숙련 인력 부족 문제를 해결하면서 제조 공정의 생산성을 높입니다. GrindingHub에 제시된 방법의 예시로, 벌크 형태의 원자재를 공급하는 방식이 있습니다.

6️⃣ Edge and surface modification improve tools

Modifying edges and surfaces enhances tool performance, improving edge stability and coating adhesion.

모서리 및 표면 개질로 인한 공구 성능 향상

에지 및 표면 개질을 통해 공구의 성능을 향상시키고 에지 안정성과 코팅 접착성을 개선합니다.

7️⃣ Targeted process and component control

Precise in-process and post-process measurements ensure high-quality machining results without altering sensitive surfaces.

목표 프로세스 및 구성 요소 제어

민감한 표면을 변형시키지 않으면서 정확한 가공 결과를 얻기 위해서 공정 중, 공정 후의 정밀한 측정이 중요합니다.

8️⃣Networking between research and industry

Various research institutes from the field of production technology presented the results of current research projects in the GrindingSolutionPark.

연구기관와 산업 간의 네트워킹

Grinding Solution Park에서 생산 분야의 다양한 연구기관이 연구 프로젝트의 결과를 발표했습니다.

9️⃣ Meeting current challenges with innovations

Automation and digitalization at GrindingHub 2024 aim to address labor shortages and advance eco-friendly manufacturing

혁신을 통해 현재의 과제를 해결

GrindingHub 2024는 자동화 및 디지털화에 주목함으로써 숙련된 인력 부족을 극복하고, 친환경 제조 공정을 발전시키는 것을 목표로 합니다.

If you would like to learn more about the grinding technologies highlighted at GrindingHub 2024, please visit the link below!

GrindingHub 2024가 주목하는 연삭 기술에 대해 더 자세히 알고 싶다면 아래 링크를 참고해주세요!

ORSKOREA: Stepping onto the Global Stage

세계로 뻗어나가는 ORSKOREA

At this exhibition, ORSKOREA discussed how to introduce its innovative products to more countries and also met with chefs to discuss whether it can supply equipment to compete in the European and Indian markets. This process will greatly contribute to the export potential of the European and Indian markets.

The Chairman of ORS Bearings managed the ORSKOREA booth, engaging in in-depth discussions about the current business plans being prepared in Korea.

It is expected that this opportunity will have a positive impact, fostering closer cooperation and mutual growth between ORS Bearings and ORSKOREA.

This exhibition was a valuable opportunity to expand our global network and widely promote ORSKOREA's technology, and the Chairman's involvement further highlighted the importance of the event.

The experience of building a global network through this exhibition will serve as a driving force for ORSKOREA to successfully establish itself in the global market.

이번 전시회에서 ORSKOREA는 혁신적인 제품을 더 많은 국가에 알리기 위해 선보이며, 딜러분들과도 만나 유럽 및 인도 시장으로의 진출을 목표로 장비를 공급할 수 있는지 논의했습니다. 이 과정을 통해 유럽과 인도 시장으로의 수출 가능성을 크게 높이는 중요한 계기가 되었습니다.

ORS Bearings 회장님도 ORSKOREA 부스 운영에 참여하시어 현재 한국에서 준비하고 있는 사업에 대한 심도 있는 논의를 나누었습니다.

ORS Bearing과 ORSKOREA가 이번 기회로 더욱 긴밀한 협력을 통해 동반 성장을 도모할 수 있는 긍정적인 효과를 가져올 것으로 기대됩니다.

이번 전시회는 글로벌 네트워크를 확장하고, 오알에스코리아의 기술을 널리 알리는 소중한 기회였으며, 회장님의 참여로 이번 전시회의 중요성이 더욱 부각되었습니다.

전시회를 통해 글로벌 네트워크를 형성한 경험은, ORSKOREA가 세계 시장에서 성공적으로 자리 잡기 위한 원동력이 될 것입니다.

GrindingHub 2024: Advancing Towards

the Future of Manufacturing

GrindingHub 2024: 제조업의 미래를 향한 도약

Dr. Markus Heering, executive director of the VDW (German Machine Tools Builder’s Association, said,

"Grinding technology is a small but thriving sector that represents one of the most important metalworking processes."

At GrindingHub 2024, the new hub for international grinding technology, ORSKOREA is making strides toward advancing the manufacturing industry.

You can check out the related article below.

GrindingHub2024의 행사 주최자인 VDW 전무이사 마르쿠스 히링 박사는 이와 같이 발언했습니다.

"연삭 기술은 작지만, 가장 중요한 금속 가공 공정 중 하나입니다."

전세계 연삭 기술을 확인할 수 있는 전시회 GrindingHub 2024를 통해 오알에스코리아는 제조업계의 발전을 향해 도약하고 있습니다.

관련 기사를 아래에서 확인 할 수 있습니다.

Discover what METALTECH is all about and the cutting-edge technologies ORSKOREA showcased there.

다음 포스트는 미국 IMTS 전시회 방문 후기로 이어집니다!! IMTS는 어떤 전시회인지, 오알에스코리아는 어떤 기술을 선보였는지 만나보세요!!

If you missed us at GrindingHub 2024, don't worry!

You can catch our machine tools and spindles at the ORSKOREA booth during IMTS 2024 in Chicago, from September 9th to 14th. We look forward to seeing you there!

GrindingHub 2024에 전시했던 공작 기계와 스핀들은 올해 9월 9일부터 14일까지 시카고에서 열리는 IMTS 2024 전시회 오알에스코리아 부스에서 만나보실 수 있으니 많은 관심 부탁드립니다!